Clearance-Sized Particulates (CSP) do the greatest damage to engines!

Here is a report prepared by the National Filter Manufacturer’s Council on CSP’s:

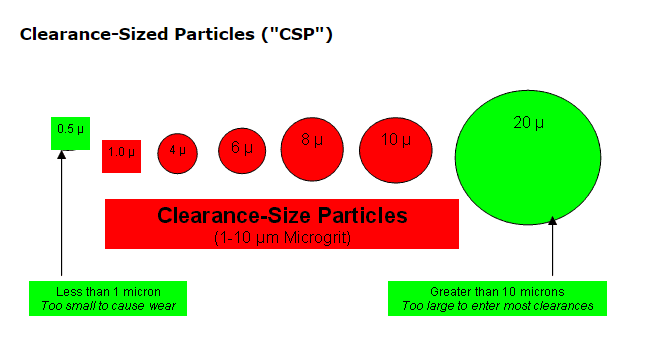

Particles in the oil film moving within the clearances between the moving parts are called Clearance-Sized Particles or CSP’s.

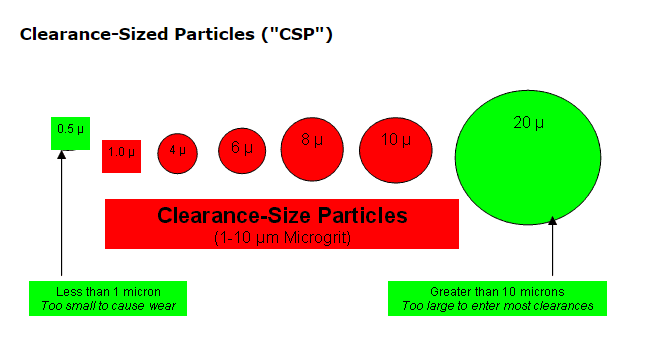

The majority of the clearances between the engine’s moving parts are between 1 and 10 microns, hence CSP’s are primarily in the 1 to 10-micron range.

The CSP’s cause the majority of engine wear and friction. CSP’s have been called “liquid sandpaper” to describe the insoluble slurry of micro-particle, which is continuously recirculated between the moving parts, causing additional wear and friction within the engine’s moving parts, such as the piston rings and cylinder wall, rod bearings and piston pin bushings.

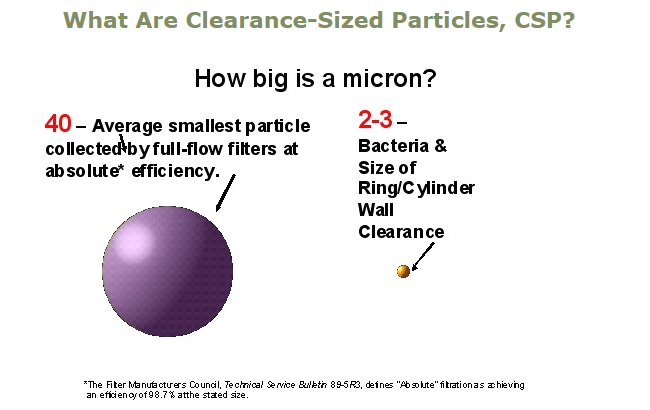

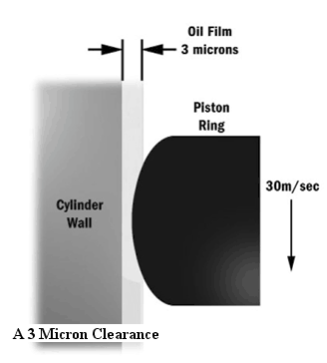

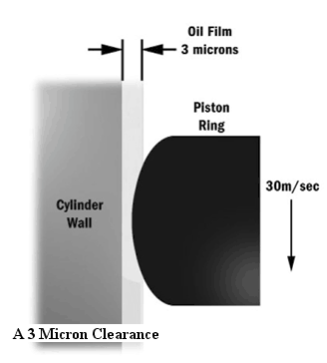

Illustrated below is a typical engine clearance. The size of the oil film between a cylinder wall and the piston ring is approximately 3 microns, the size of bacteria. If the 3-micron oil film is not carrying an abrasive clearance sized particle, there is minimal wear. If the oil film is dirty, carrying CSP’s between these parts, significant wear and friction will be created.

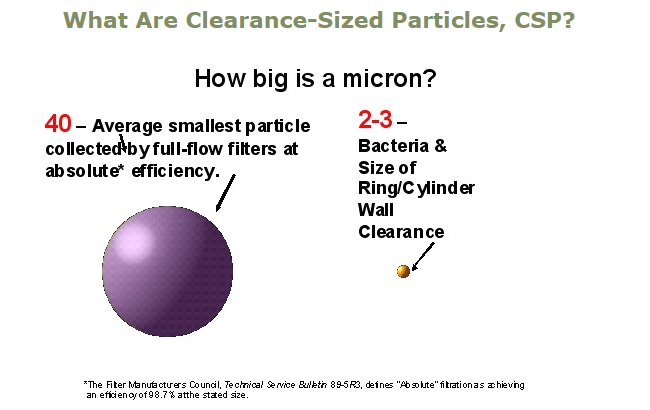

As illustrated, the size of the particle is critical! A 20-micron particle will not cause damage because it Is too large to enter the 3-micron clearance. A .01 micron-sized particle is small enough to enter the 3- micron clearance but is not large enough to wedge between the moving parts to cause wear. For the ring/cylinder 3-micron clearance, the most harmful CSP’s are 2 to 3 micron particles.

As illustrated, the size of the particle is critical! A 20-micron particle will not cause damage because it Is too large to enter the 3-micron clearance. A .01 micron-sized particle is small enough to enter the 3- micron clearance but is not large enough to wedge between the moving parts to cause wear. For the ring/cylinder 3-micron clearance, the most harmful CSP’s are 2 to 3 micron particles.

What are the sources of Particle Contamination?

There are three major causes of particle contamination:

- Engine Operation: All engines — whether fueled by diesel, bio-diesel, LNG, CNG or gasoline create CSP’s through the movement of engine parts, creating wear metals, which build up in the oil film. Abrasive CSP’s are continuously recirculated, producing more wear. The more CSP’s, the faster internal parts wear.

- Fresh Oil: Even fresh oil contains particle contamination, esp. when the oil is stored in a central tank and pumped through long hoses into the crankcase. To the naked eye, the fresh oil, either yellowish-green or golden-brown, looks “clean”. Since the lower limits of human vision is approximately 40-50 microns, the harmful bacteria-sized 1-10 CSP micro-grit is invisible.

- Air: There are invisible CSP’s in the air, such as silicon dioxide particles in ash from smoke stacks where coal is burned. Particle contamination is esp. dangerous in high dust environments. Silica particles are extremely harmful because they are harder than engine parts. High levels of CSP silica is a major cause of engine wear and damage.

Do Full Flow Filters Remove CSP’s?

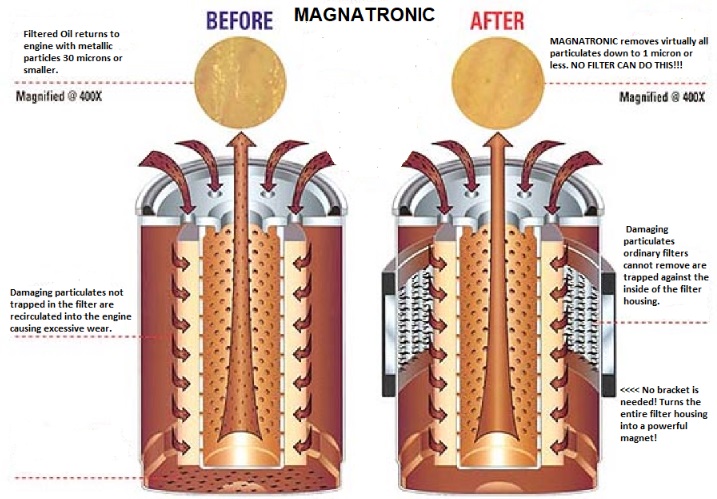

No. Engines have at least one full-flow filters. It operates inline with a high oil flow rate, typically 12 to 15 gallons per minute at 170-200 degrees with a 25-65 psi. Full-flow filters can filter down to approximately 30-45 microns on average with absolute efficiency (iY 98.7%) but cannot prevent the buildup of 1 to 10-micron contamination.

The Full Flow filter is directly between the oil pump and lubricated parts. All the oil from the oil pump must pass through the full-flow filter before it enters the engine to lubricate and cool the rapidly moving parts.

To avoid starving the engine of lubricating oil, the filter media must be relatively porous and is usually made from synthetic materials.

If the full-flow filter clogs, the engine’s bypass safety valve opens. The full-flow filter is taken offline to allow the engine’s oil to flow through the engine while bypassing the filter.

When the full-flow filter is offline, there is no engine oil filtration.

Does MAGNATRONIC remove CSP’s?

Without a doubt, MAGNATRONIC is the solution that makes more sense! Without brackets or complicated installation, you can put MAGNATRONIC to work on your oil filter instantly and get the protection only MAGNATRONIC can provide!

MAGNATRONIC, with 600 x the power of a regular magnet, transforms your existing engine oil filter by magnetizing the filter housing. As oil flows through the engine and into the filter, particulates that are not trapped in the filter media are trapped against the inside of the filter housing until the filter change.

Click HERE to find out more about MAGNATRONIC and to Order!

Do CSP’s Shorten Engine Life?

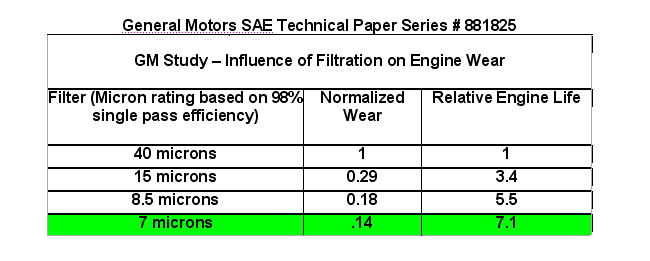

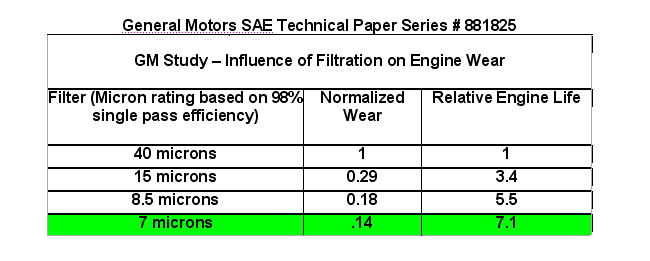

Yes! General Motors published a SAE report on the relationship between small micron particle contamination and engine life. The test evaluated the impact of cleaner oil on engine life.

The GM study reported that when the lubrication oil is filtered down to 7 microns, engine wear is minimized, and relative engine life is more than five times longer. The following graph illustrates the relationship between particle contamination and engine life:

Proof positive you need a MAGNATRONIC for the job! Imagine the payoff with companies who operate fleets!

One More Engine Oil Filter Study further proving the need for a device like MAGNATRONIC!

The SAE J806 test uses a single-pass test, checking for contaminant holding capacity, size of contaminant particles trapped, and ability to maintain clean oil. As an amendment of the J806 test, the multi-pass test also looks for filter life in hours, contaminant capacity in grams, and efficiency based on weight. The efficiency of the filter is determined only by weight through gravimetric measurement of the filtered test liquid. Typical numbers for paper filter elements are 85% (single pass) and 80% (multi-pass).

The SAE J1858 test provides both particle counting and gravimetric measurement to measure filter capacity and efficiency. Actual counts of contaminant particles by size are obtained every 10 minutes, both upstream (before the filter) and downstream (after the filter), for evaluation. From this data filtration ratio and efficiency for each contaminant particle size can be determined as well as dust capacity and pressure loss as a function of time. Typical numbers for paper element filters are 40% at 10 microns, 60% at 20 microns, 93% at 30 microns, and 97% at 40 microns.

CHOOSE the right MAGNATRONIC for your needs!

Standard for cars, light trucks, lawn tractors, atv’s, motorcycles, snowmobiles .

MAGNUM for trucks, farming equipment, construction machinery, logging machinery, evaporators, yachts and many other applications

ORDER NOW – FREE SHIPPING!

STANDARD 2″ X 7.5″ $19.95

<https://www.paypal.com/ncp/payment/NFN9V2B6W24R8>

MAGNUM 4″ X 7.5″ $34.95

>https://www.paypal.com/ncp/payment/AX3UP2ZY82W5S<

RUSH ORDER? CALL 214-797-2948 NOW!

Nothing works like Magnatronic to extend engine life, significantly improve performance and increase engine life by as much as 5 X Times!

Nothing works like Magnatronic to extend engine life, significantly improve performance and increase engine life by as much as 5 X Times!